Capacitors are fundamental components in electronic circuits. While it is possible to design some basic circuits without capacitors, many electronic systems rely heavily on capacitors for stable and reliable operation. Understanding the role of capacitors in your specific application helps ensure optimal circuit design and functionality. In this article, we’ll dive into the world of capacitors, exploring their different types, functions, and practical uses in electronic circuits.

What is a Capacitor?

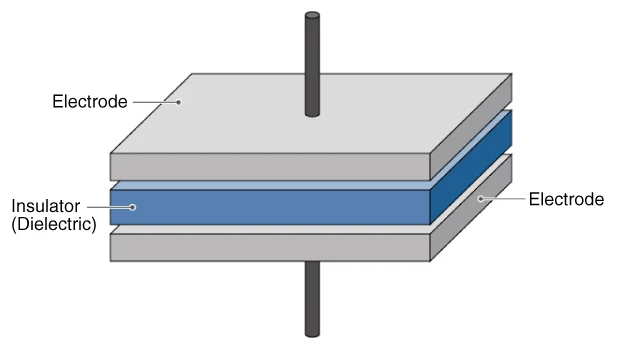

A capacitor is a passive electronic component that consists of two conductive plates (electrodes) separated by an insulating material called a dielectric. It stores electrical energy in an electric field. When voltage is applied across the plates, an electric field is generated, allowing the capacitor to store the energy. A capacitor is so-called because it has the “capacity” to store energy. Capacitors are essential for managing and stabilizing voltage and current in circuits.

A capacitor allows voltage to be present across the plates in the form of an electrical charge. There are two types of electrical charge: positive (+) charge in the form of protons and negative (-) charge in the form of electrons. When a DC voltage is applied across a capacitor, positive charge accumulates on one plate and negative charge on the other, creating a potential difference. For each positive charge that arrives at one plate, a corresponding negative charge leaves the other plate. Once the capacitor reaches its steady state, no electrical current can flow through the capacitor itself because the dielectric layer separating the plates acts as an insulator.

Capacitors store energy in the form of electrical charge on the plates. The larger the plates or the smaller the distance between them, the greater the capacitance and the more charge the capacitor can hold for a given voltage. In other words, larger plates and smaller separation result in higher capacitance.

Standard Units of Capacitance

Capacitance is the ability of a capacitor to store an electrical charge, measured in farads (F). However, because the farad is a very large unit, capacitors in most electronic applications are typically measured in smaller units: microfarads (μF), nanofarads (nF), and picofarads (pF).

Microfarad (μF)

1μF = 1/1,000,000 = 0.000001 = 10-6 F

Nanofarad (nF)

1nF = 1/1,000,000,000 = 0.000000001 = 10-9 F

Picofarad (pF)

1pF = 1/1,000,000,000,000 = 0.000000000001 = 10-12 F

Types of Capacitors

1. Ceramic Capacitors

A ceramic capacitor consists of a ceramic material as the dielectric, sandwiched between two conductive plates. The ceramic material determines the capacitor’s properties and performance characteristics. These capacitors come in various shapes and sizes, with the most common types being multilayer ceramic capacitors (MLCCs) and ceramic disc capacitors. They are non-polarized, meaning they can be connected in any direction. Capacitance values are typically measured in picofarads (pF), nanofarads (nF), and microfarads (μF).

Applications:

Power supply bypassing and decoupling: Ceramic capacitors are used to filter out noise from power supply lines and provide a stable voltage. They are often placed close to the power pins of ICs. For example, a 0.1 μF MLCC is commonly used for decoupling in microcontroller circuits.

Signal filtering: Ceramic capacitors are used in various filter circuits to pass or block certain frequency ranges. They are used in both low-pass and high-pass filters. For instance, a 10 nF capacitor might be used in an audio crossover network.

Resonant Circuits: Ceramic capacitors are used in LC (inductor-capacitor) resonant circuits for tuning and frequency selection. For example, a 22 pF capacitor might be used in an RF transmitter circuit.

2. Electrolytic Capacitors

An electrolytic capacitor is a type of capacitor that uses an electrolyte to achieve a larger capacitance than other capacitor types. It consists of an anode (a metal plate), a dielectric (an oxide layer), and a cathode (a liquid or solid electrolyte). Due to their construction, electrolytic capacitors are polarized, meaning they have a positive and negative terminal. Capacitance values of electrolytic capacitors are typically measured in microfarads (μF). When using them, ensure correct polarity when connecting electrolytic capacitors in circuits to prevent damage. Electrolytic capacitors are more suitable for conventional application conditions

Types of Electrolytic Capacitors

Aluminum Electrolytic Capacitors

These capacitors use aluminum foil and an electrolyte to provide high capacitance values. They are the most common type of electrolytic capacitor. They are generally inexpensive and offer high capacitance values, but they have higher ESR and a shorter lifespan. They are used in power supply filtering, audio circuits, and energy storage applications.

Tantalum Electrolytic Capacitors

These capacitors use tantalum for the anode and a solid or liquid electrolyte. They offer better performance and reliability but are more expensive than aluminum electrolytic capacitors. They are used in precision timing circuits, military and aerospace applications, and portable electronics.

Polymer Electrolytic Capacitors

These capacitors use a conductive polymer as the electrolyte, providing lower ESR (Equivalent Series Resistance) and higher stability. Polymer capacitors have a long lifespan, but they may not be suitable for high-capacitance applications. They can be used to smooth out the voltage from a power source to a sensitive circuit, reducing power noise. In such applications, they can easily replace standard electrolytic capacitors, provided that the operating voltage is sufficiently low.

3. Film Capacitors

Film capacitors use a thin plastic film as the dielectric, which is either metalized or has metal foil electrodes. The film is rolled or stacked to form the capacitor. They have excellent stability, low inductance, and low ESR. They are also non-polarized, meaning they can be connected in any direction in a circuit. Film capacitors are much better for high temperature, high frequency, and high voltage application conditions.

4. Supercapacitors

Supercapacitors, also known as ultracapacitors or electric double-layer capacitors (EDLCs), store energy through the separation of charges in an electric double layer at the interface between a solid electrode and an electrolyte. Unlike conventional capacitors that use a dielectric material, supercapacitors utilize high surface area electrodes and thin electrolytic separators to achieve much higher capacitance values. They offer high capacitance values, rapid charge and discharge capabilities, and a long cycle life, making them ideal for various applications requiring quick energy bursts and efficient energy storage. Such applications are used in automobiles, buses, trains, cranes, and elevators. Supercapacitors can be connected in parallel with batteries to provide additional energy during peak loads, or in series for higher voltage applications.

Practical Applications of Capacitors

- Energy Storage: Capacitors store energy for quick release when needed.

- Power Conditioning: They filter and smooth the output of power supplies.

- Signal Coupling and Decoupling: Capacitors block DC signals while allowing AC signals to pass, ensuring signal integrity in various stages of an electronic circuit.

- Timing and Oscillator Circuits: Combining with resistors, capacitors are used to create timing elements in oscillators and timer circuits.

- Tuning Circuits: They are used to adjust the frequency response of tuning circuits in radios and televisions.

- Motor Starters: Capacitors provide the necessary phase shift to start single-phase induction motors.

- Electronic Filters: Capacitors form part of filter circuits to remove unwanted frequencies from signals.

- Energy Harvesting: They are used to store energy harvested from ambient sources like solar panels or kinetic energy.

- Decoupling and Bypassing: They decouple power supplies from various circuit stages to prevent noise and interference.

- Lighting Systems: Capacitors improve power factor and provide the necessary phase shift in lighting ballasts.

- Electrostatic Protection: Capacitors protect electronic circuits from electrostatic discharge (ESD).

- Pulse Power Applications: They deliver quick bursts of power in pulsed applications such as lasers and defibrillators.

Capacitors are versatile components and are indispensable in the world of electronics. By understanding the different types of capacitors and their applications, you can effectively utilize them in your projects to achieve desired performance and reliability.

Explore our range of capacitors available at Any Component Lab and start experimenting with these essential components in your next project!

Shop Now

Stay tuned for more insightful articles and tutorials on electronic components and their applications. Until next time, stay curious!